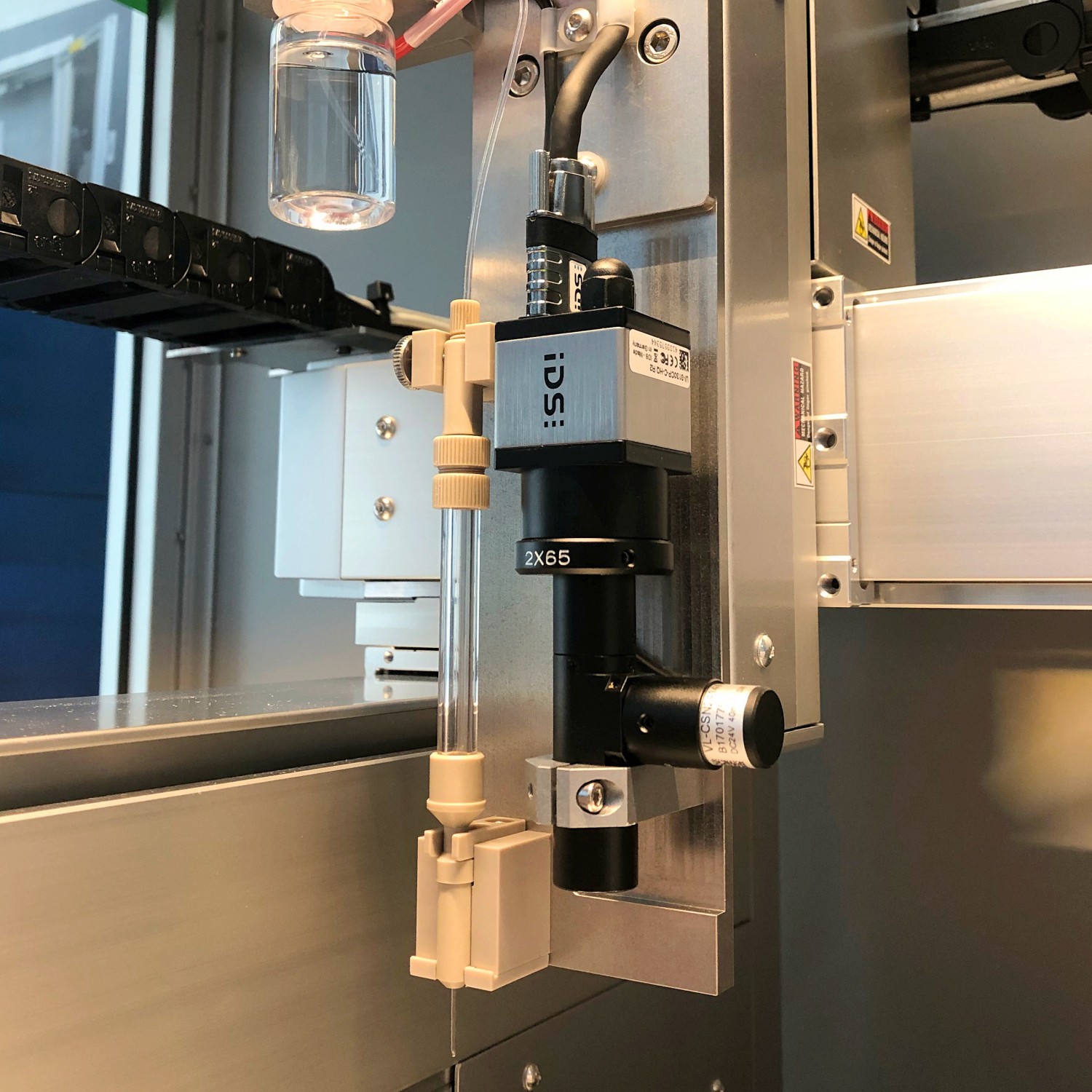

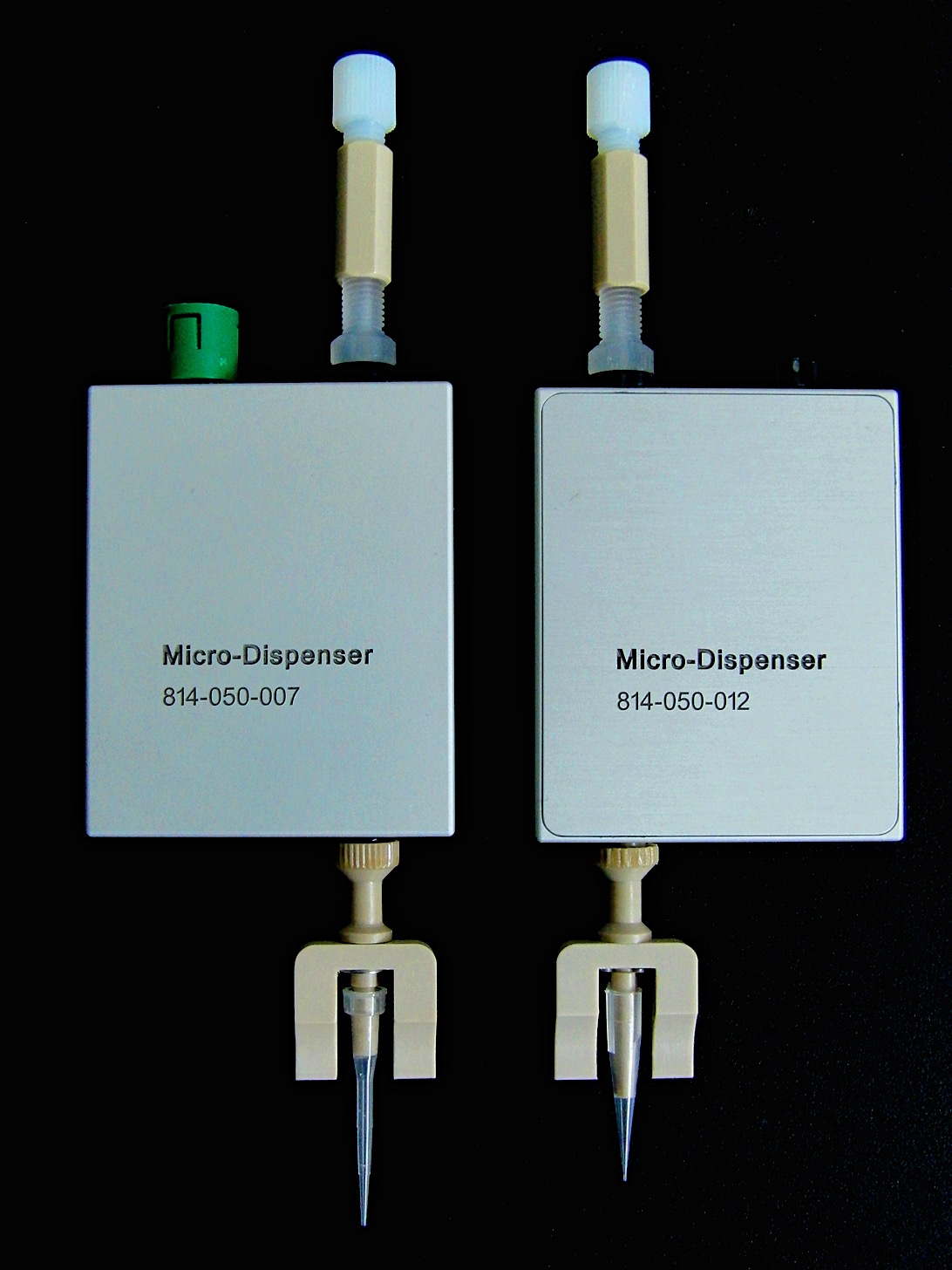

NON-CONTACT MICRODISPENSERS

The non-contact microdispensers are dedicated for spotting of up to few hundred different samples on different targets. The volume of the dispensed sample is controlled by the microdispenser and the spot size is determined by properties of samples and target surface. The spotting is carried out without touching the target surface, which ensures perfect reproducibility, no contamination, and no damage of the target. Our non-contact microdispensers are based on piezo driven direct displacement of the liquid or flow-based liquid displacement based on solenoid valve.

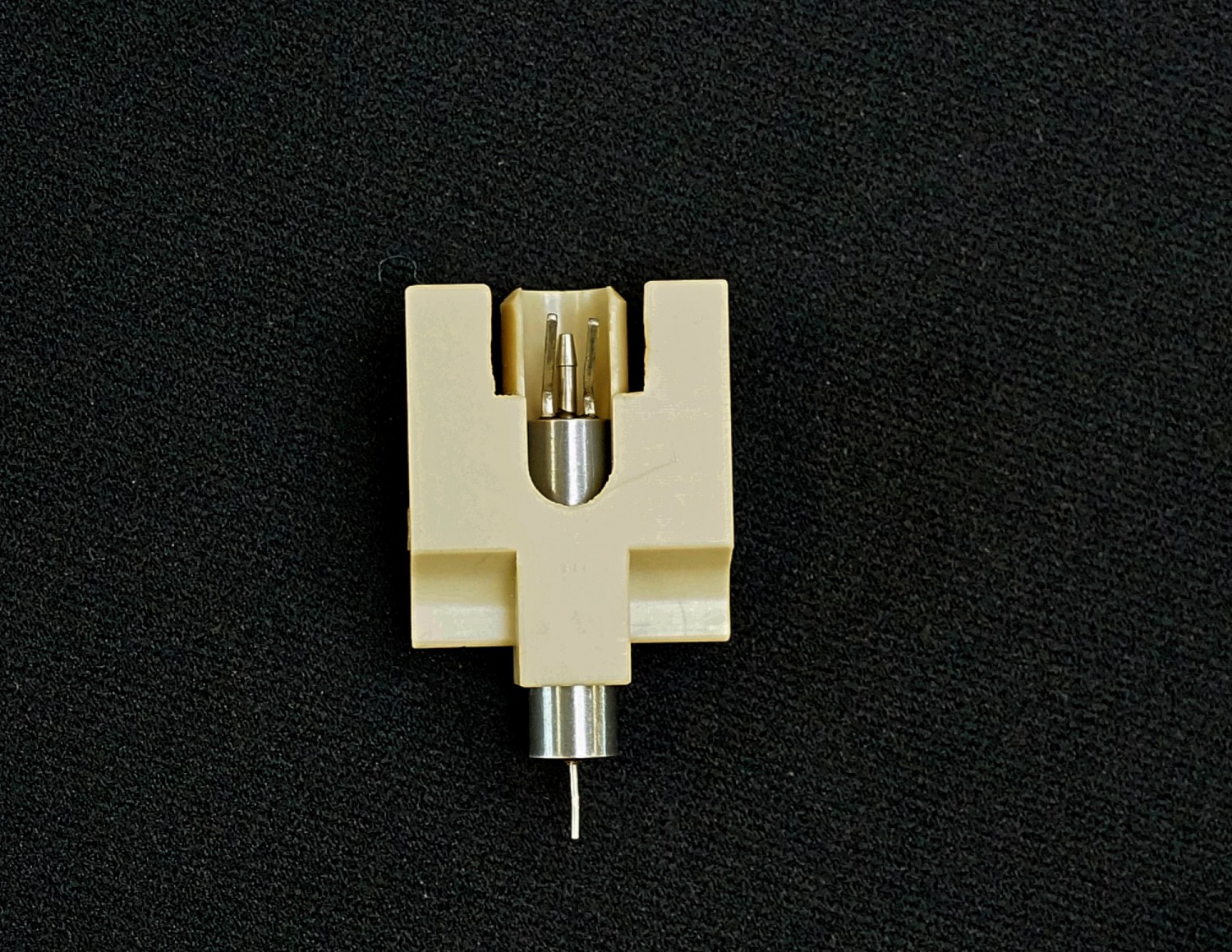

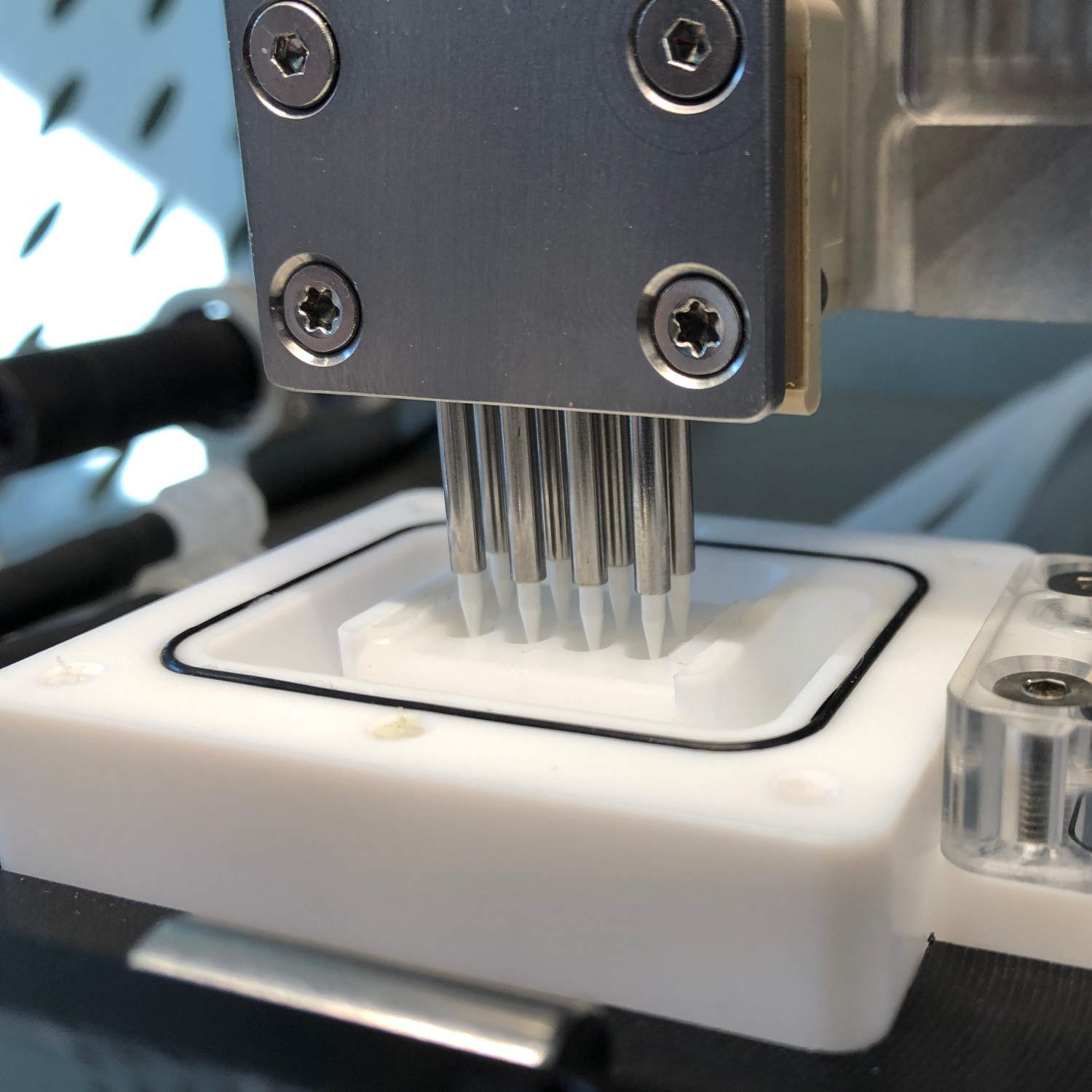

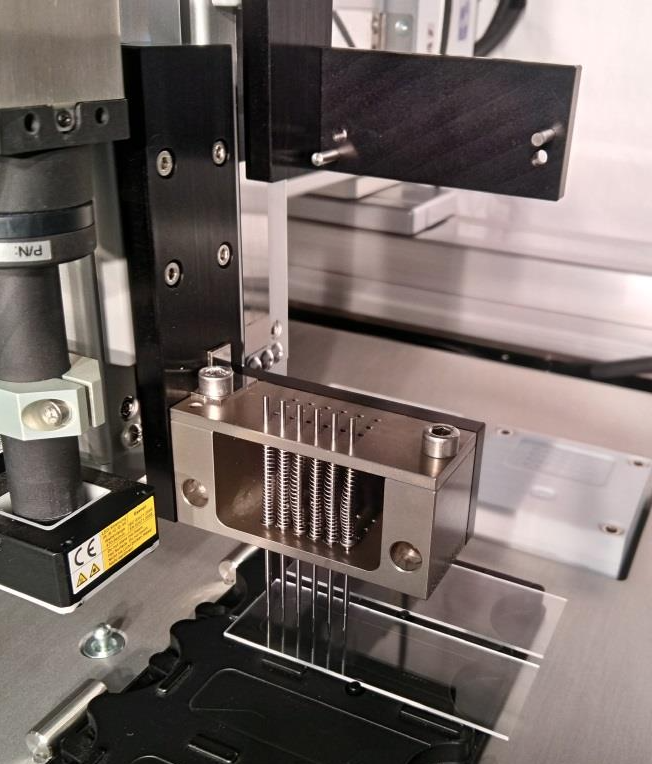

CONTACT MICRODISPENSERS

The main advantage of using contact microdispensers is enabling printing of more than thousands of samples. The sample solution is printed on the target by a pin, where a small drop is hanging at the blunt end of a solid pin, flowing out of a small gap, in case of split pin or one end of a capillary, at capillary pins. The pin is in contact with the surface for variable time, releases the requested volume and creates a spot. Size of the spot is dependent on the viscosity of the sample and duration of the contact between the pin and surface. M2 contact microdispensers are purely passive, have no electrically induced forces and are mechanically and materially different from M2 non-contact dispensers.