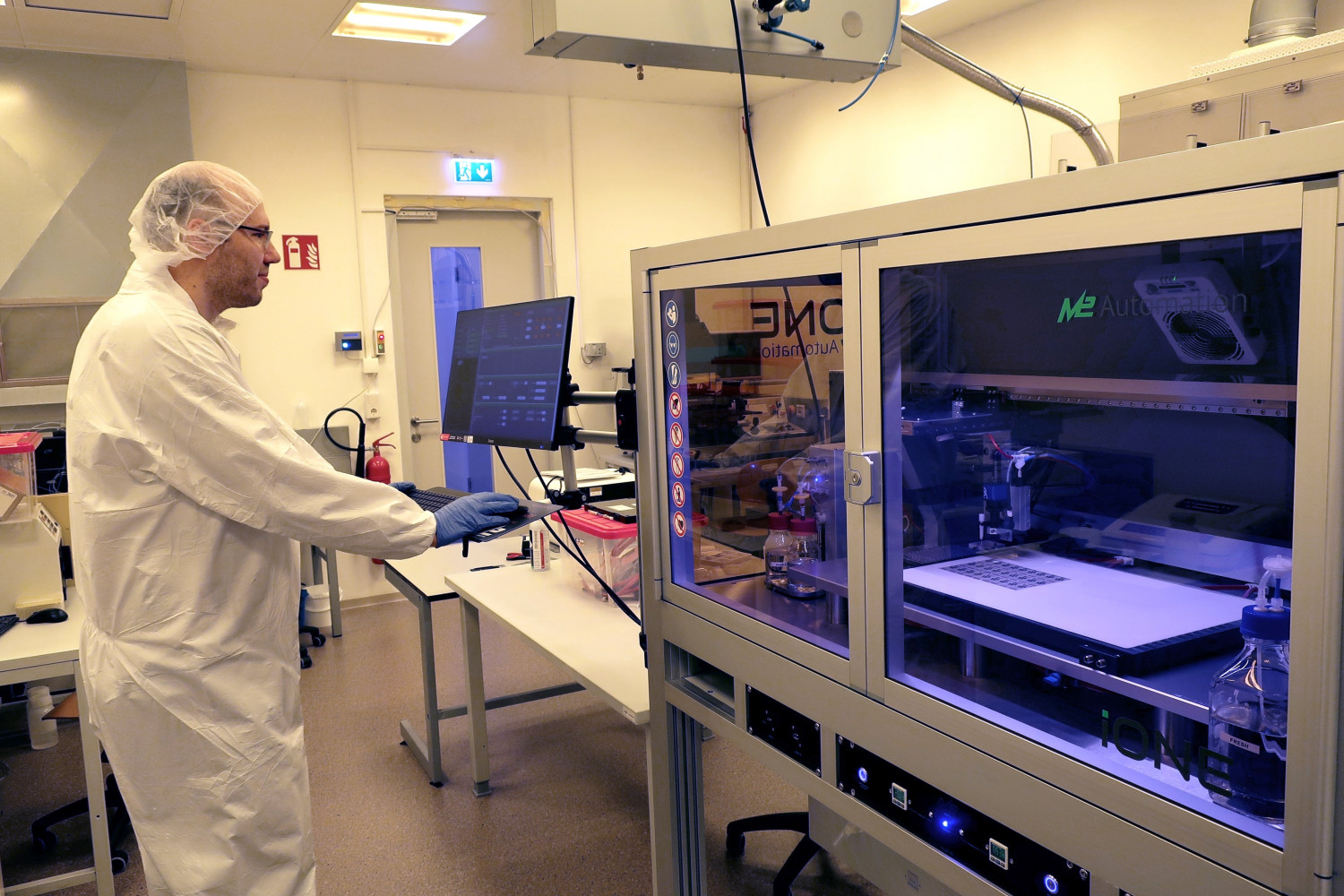

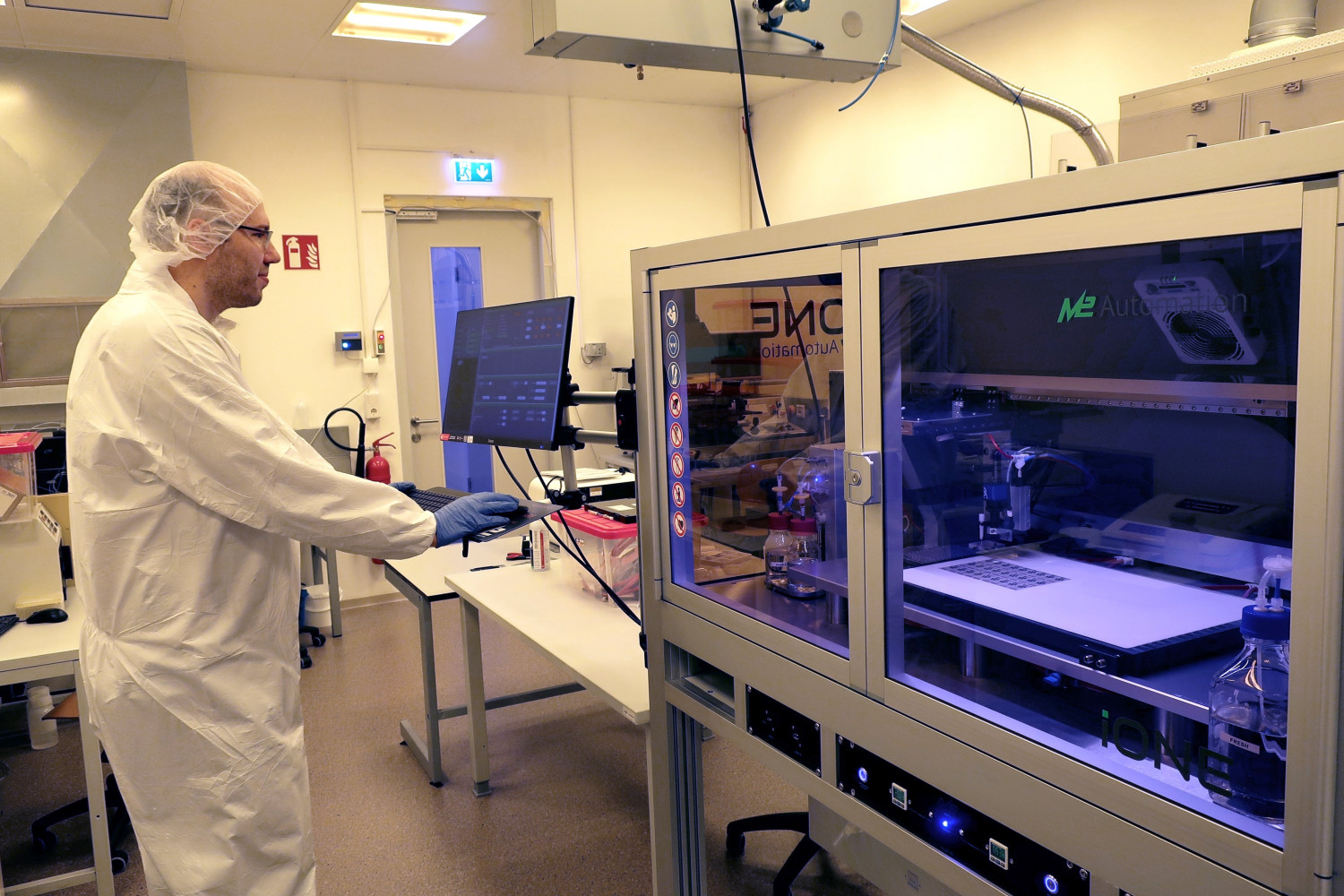

To meet the demand for precise and reproducible surface modification of sensors and microfluidics, AIT is equipped with state-of-the-art non-contact liquid handling systems such as the M2-Automation iONE-600 dispenser, known for its precision in position (±3 µm) and volume control (SD 3-5%). Its pico- and nanoliter dispensing units enable precise modification of target structures (dimensions of 100 µm up to mm-scale) with (bio)ink volumes ranging from 100 pL to mL. The dispenser facilitates modification of substrates up to A3 size under a controlled atmosphere, ensuring reproducibility (humidifier, temperature control, ionizer) and efficiency.

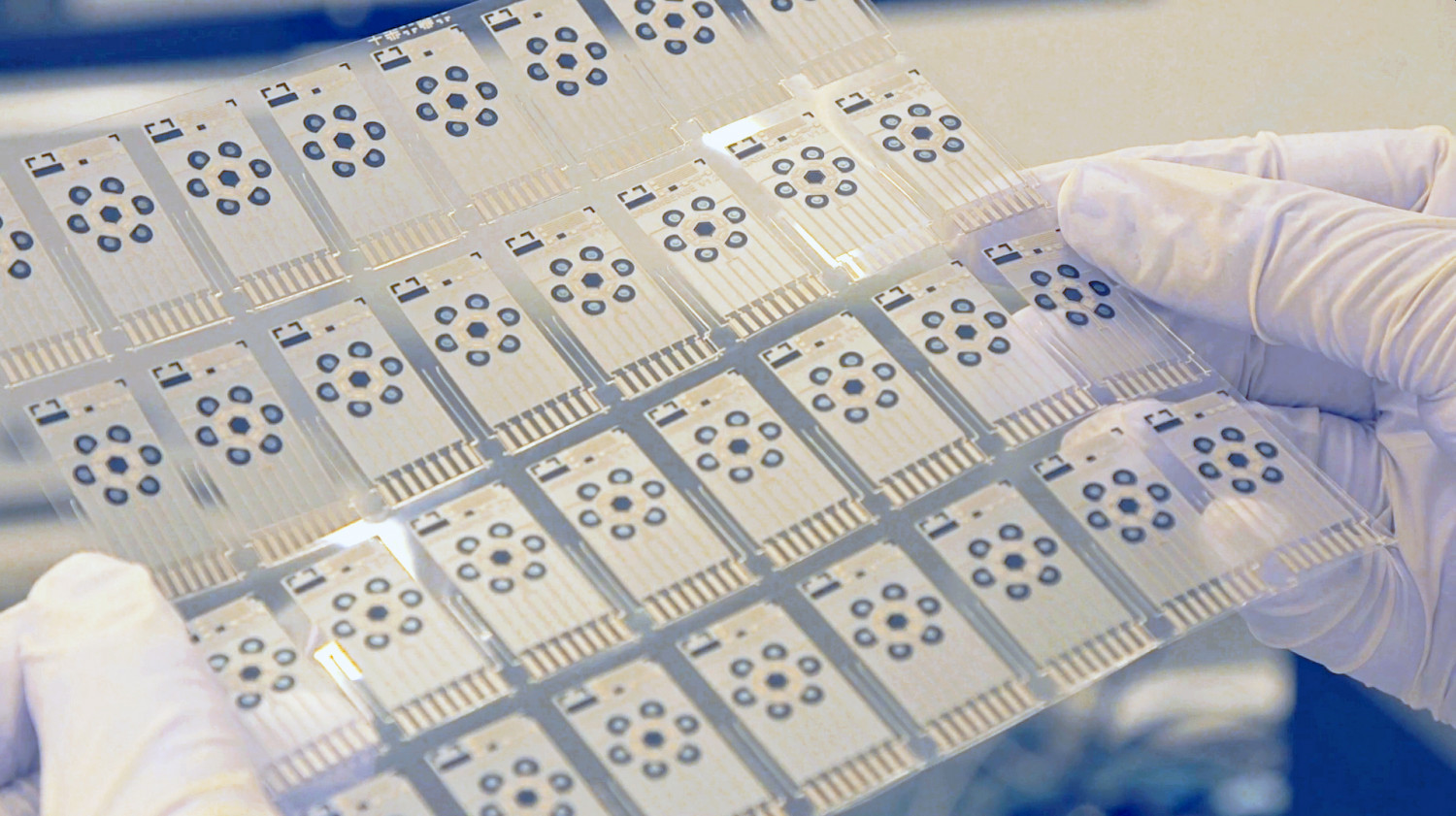

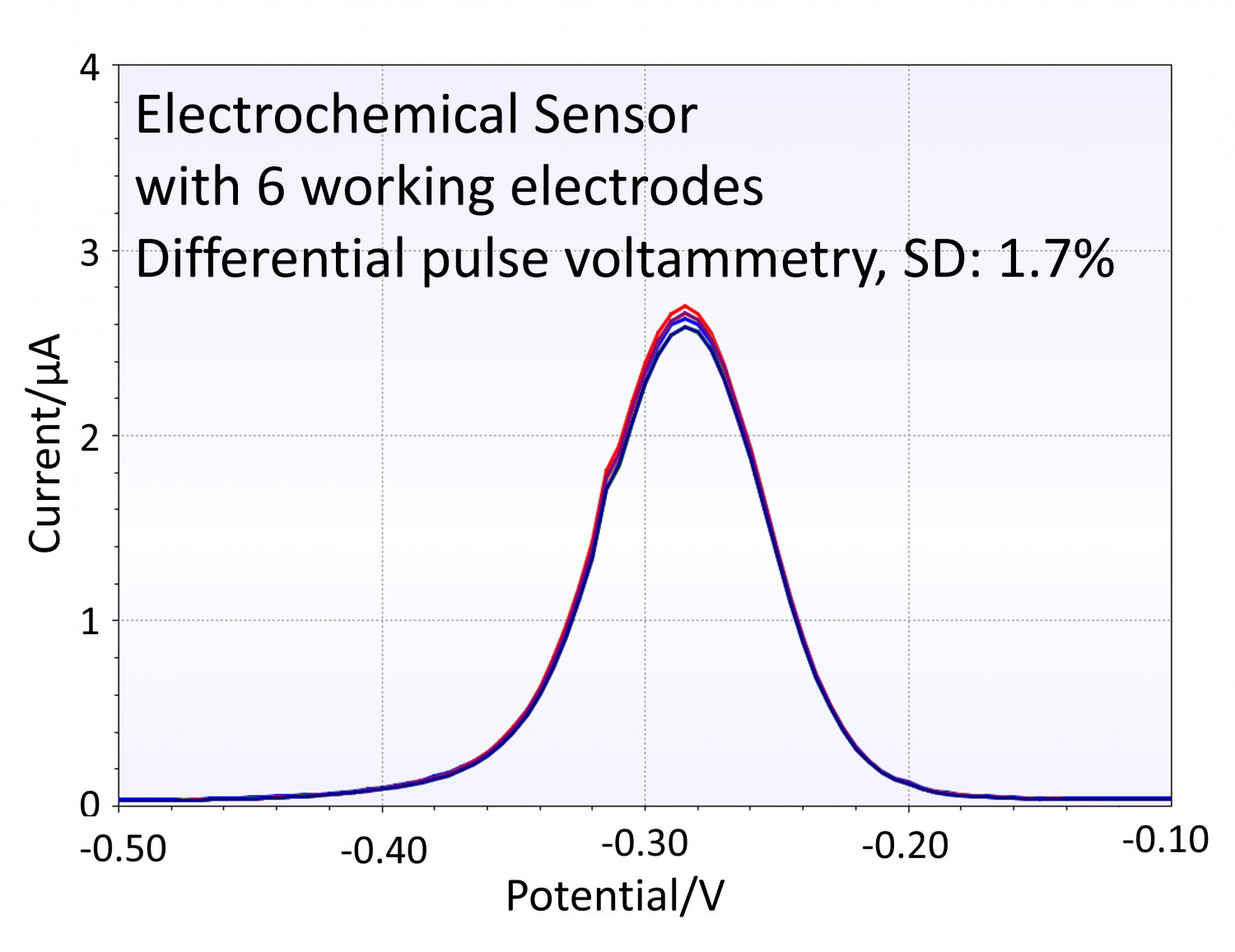

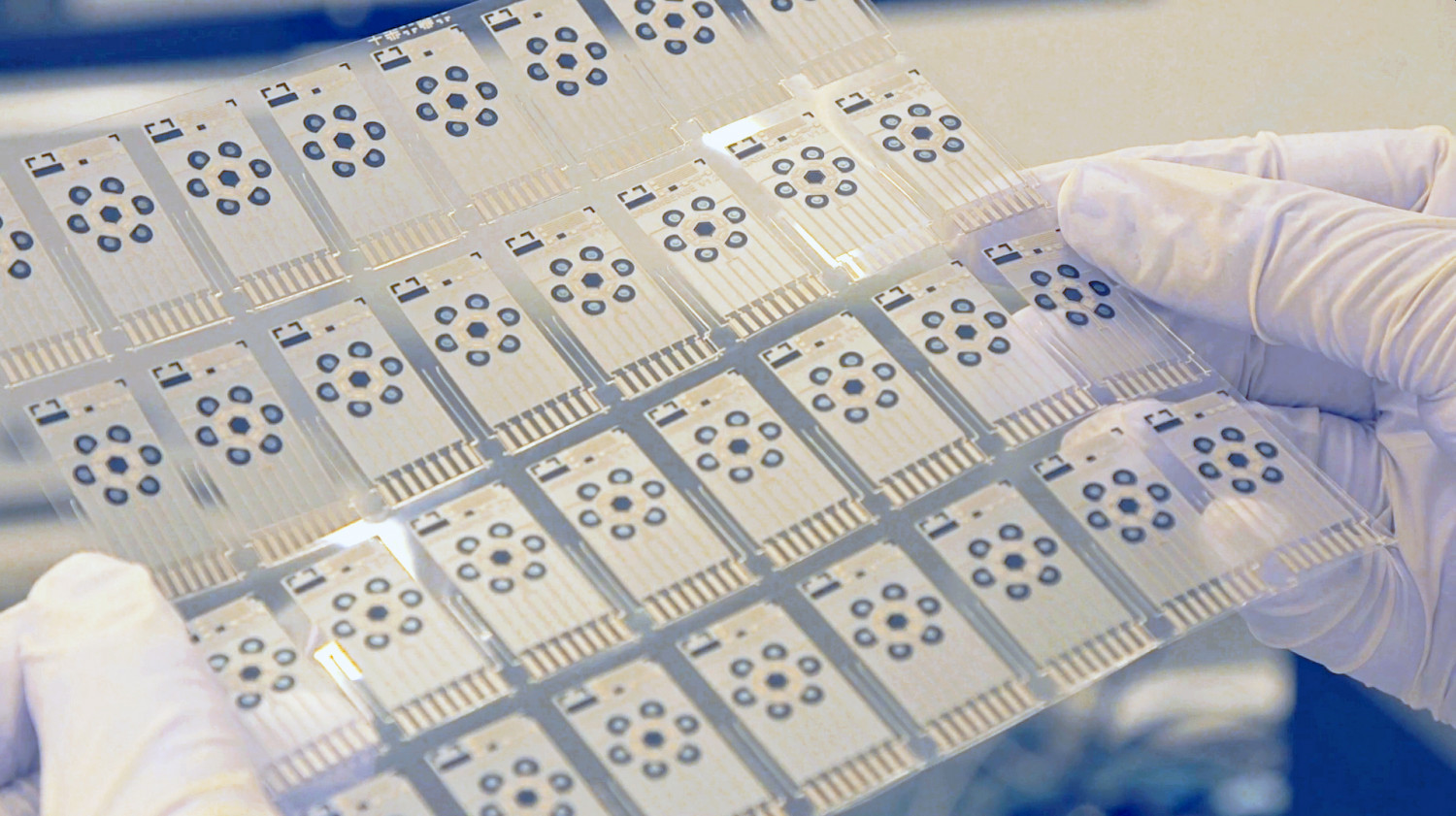

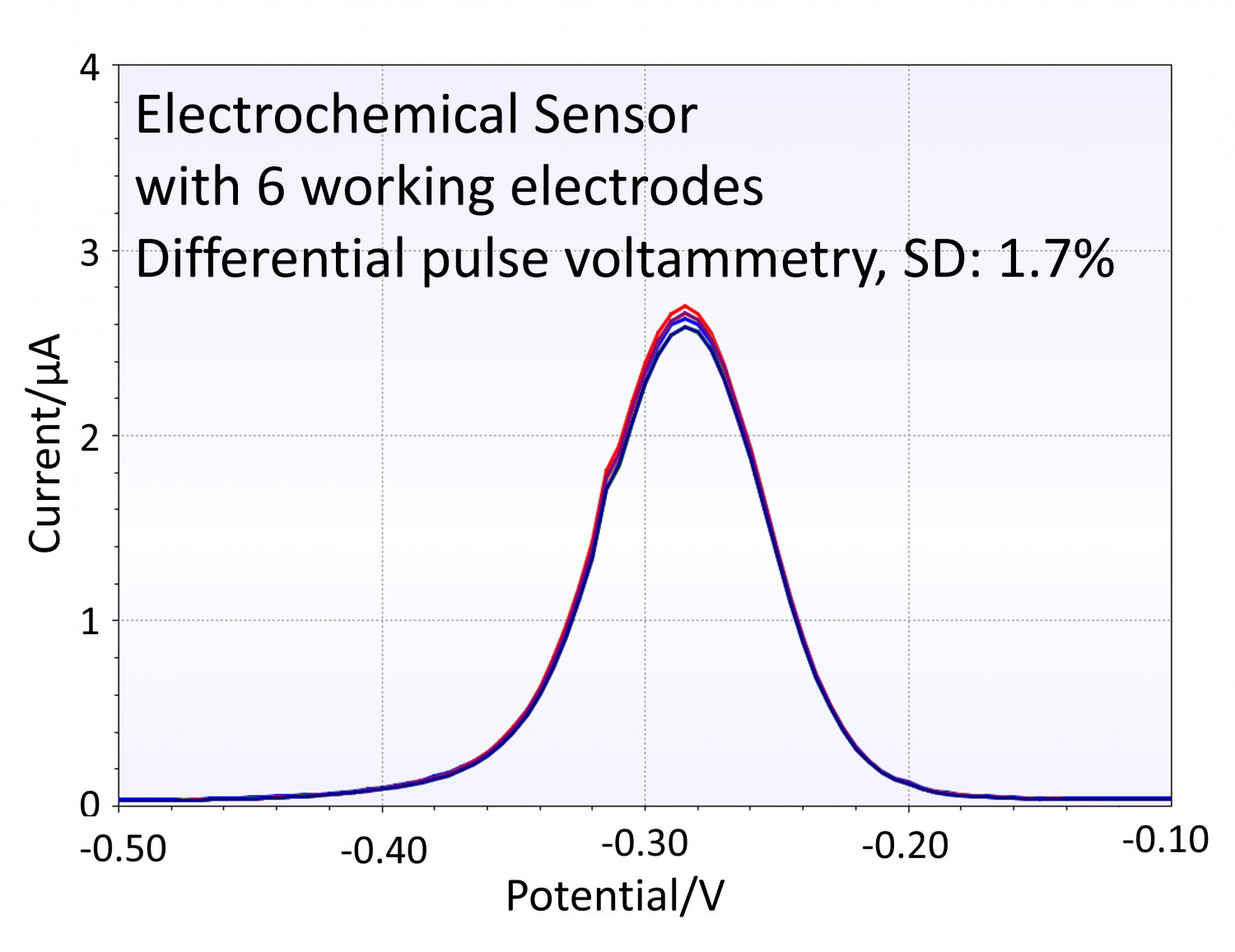

From left to right: M2-Automation iONE-600 dispenser, sensor sheet with 32 sensors, six working electrodes per sensor, 1µL of redox-active methylene blue graphene oxide composite dispensed with M2MD nanoliter dispenser, differential pulse voltammetry-based quality control of electrochemical sensor with six electrodes showing excellent reproducibility (H2020 project GreenSense 761000).