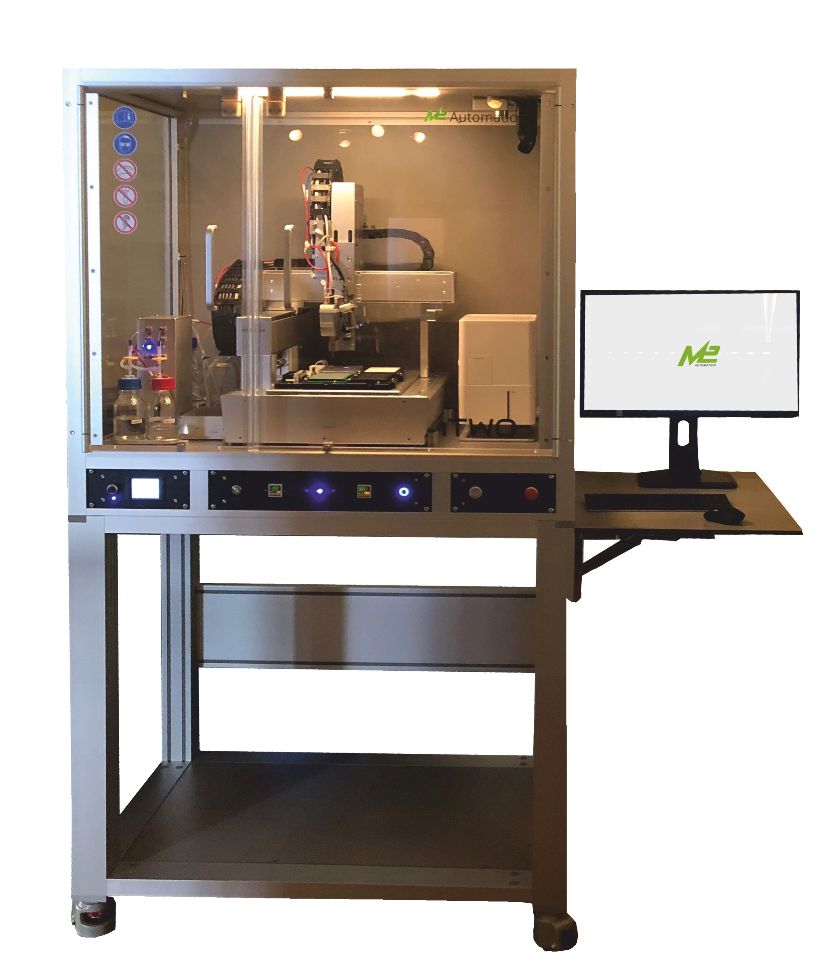

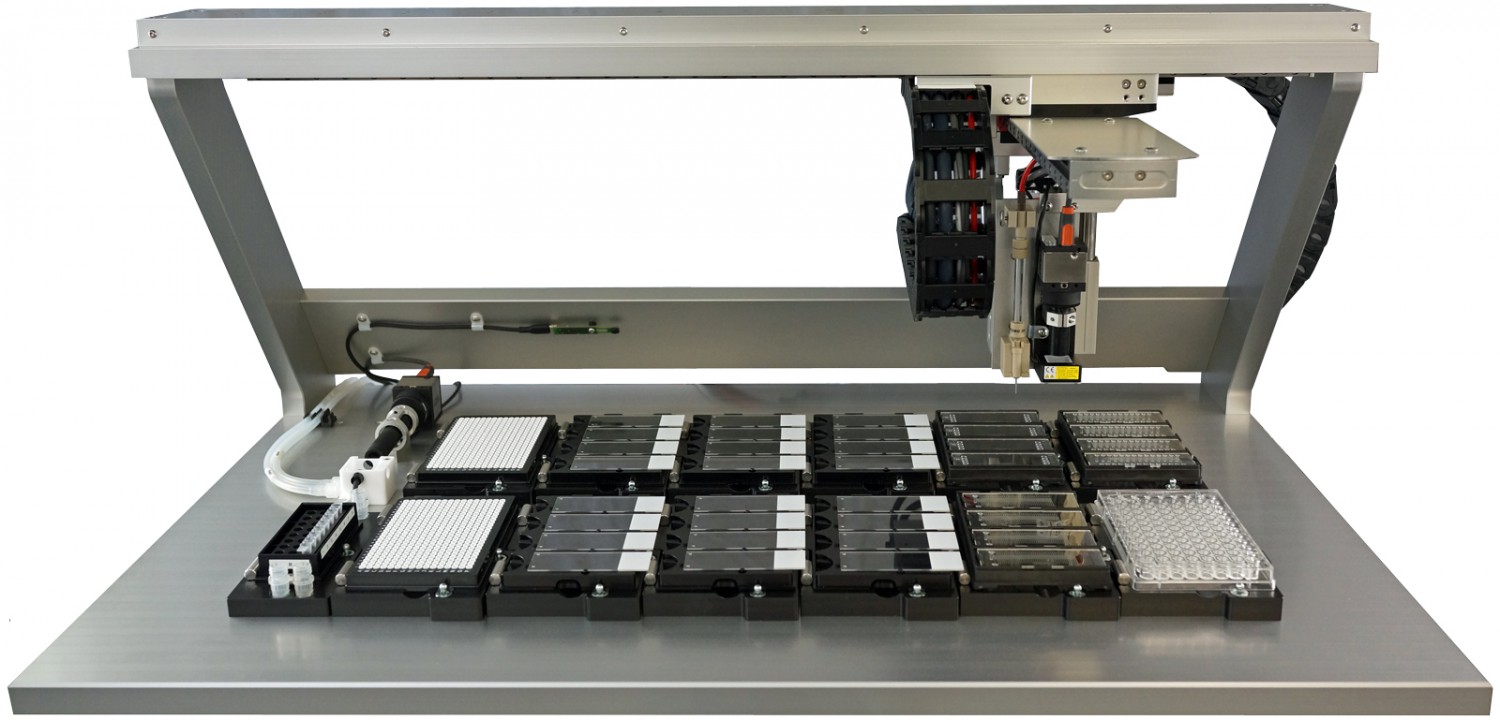

AIR FILTER

We all try to avoid contamination in our labs, within our experiments and processes. M2-Automation brings a solution — Clean Air Filtration System. With its presence we canbe sure, that particle contamination will be a thing of the past. Clean air and optimal testing and production conditions will prevail! The HEPA flow-through air filtration system eliminates particles in air, e.g. dust. These unwelcome particles in the air, within a closed testing environment, can be a critical contamination source in liquid handling process, e.g. during the production of biochips. A large HEPA filter is used as the last filter element, and the HEPA is usually combined with an enclosed M2 automation instrument.