MICROARRAY PINS

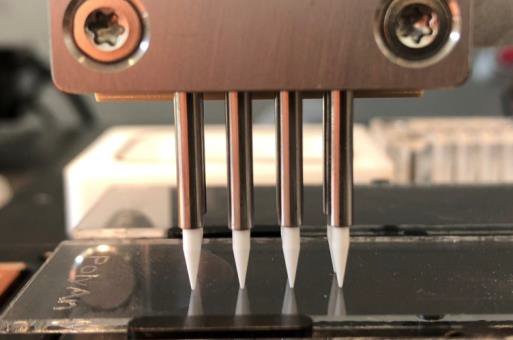

One of the most critical components of the microarray instrument for contact printing is the set of proper pins. The pins have to fulfill several requirements – uniform size, shape, height – to be ensured, that the spots will be spotted correctly. The most commonly used pins are solid and capillary pins.

Solid pins

Spotting with solid pins is based on dipping the pin into the reservoir with a sample. Afterward, pins touch the substrate, deposit there one or few spots - depending on the pin - and again return back to the reservoir with a sample. In the case of printing multiple solutions, the pins have to be properly washed and cleaned, to avoid cross-contamination. The loading, printing, and washing processes are repeated until the expected number of spots is printed on the substrate surface. The volume of the spot is depended on the diameter of the pin, the depth to which it is submerged in the sample, and the time for how long the pins stay touching the surface. Surface tension and the liquid viscosity also affect the final volume. The properties of the sample have a big impact on the spot size, the variation is higher by using plain water or salt-based buffers with high surface tension. To improve the uniformity of the spots, there have been done several innovations, mainly on the tip shape or surface texture of the pin, like controlled texturing along the length of the pin or different shapes of the tip.

Solid pins are used for low-density microarrays and are more suitable for highly viscous samples as there is no orifice and there is also no risk of clogging in the pin. The pins work very well with high surface tension buffers, are equally effective on different targets – glass, nitrocellulose and are easily cleanable.

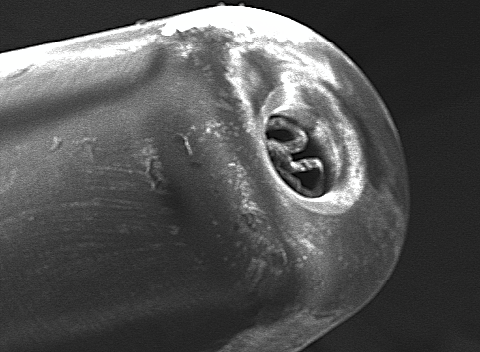

The pins are usually made of stainless steel, tungsten, titanium, or ceramics. Manufacturing of stainless-steel pins is difficult and their production can leave residues on the surface, like impurities or contaminants, which can have a negative impact on the array results. Occasionally there can be found mechanical traces, like grind marks or polish lines on the surface of the pin. Titanium is more difficult to fabricate, which leads to low accuracy of the pin shape, while tungsten carbide is susceptible to easy breaking, especially at the tip of the pin. Ceramics are robust, the pins using ceramic tips are less susceptible to damage caused by tapping forces. In general, proper pin production is necessary, as the pins should resist corrosion and deformation and their surface has to be uniform, to deliver the same spots. It is a must to be wear-resistant and necessary to withstand thousands of hits against the glass slides without any change of properties.

Capillary pins

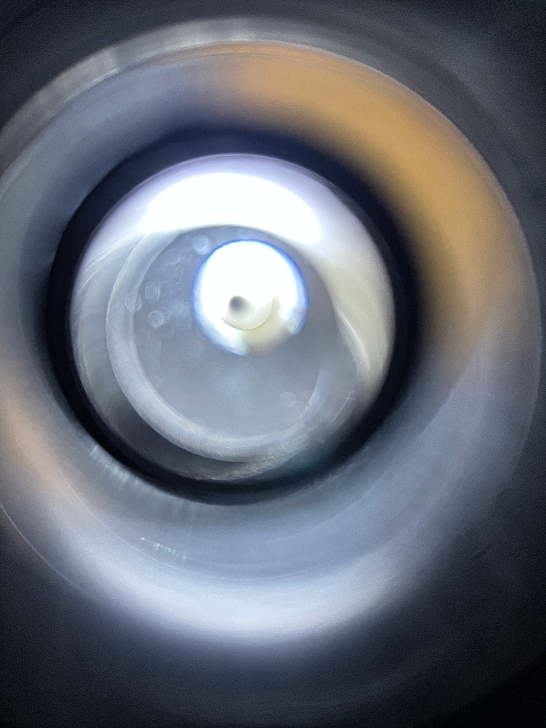

Capillary pins are pins with a tube or cannula manufactured inside the solid pin. The principle of a capillary pin is loading the liquid by capillary action and by tapping forces depositing a defined volume on the surface. Depending on the number of spots to be set in one spotting run, the pin is staying for a certain time submerged in the spotting solution. The intake of the sample is depended on the length of time the pins spend in the liquid. The liquid stays in the capillary and due to this, no evaporation can occur during the printing process.

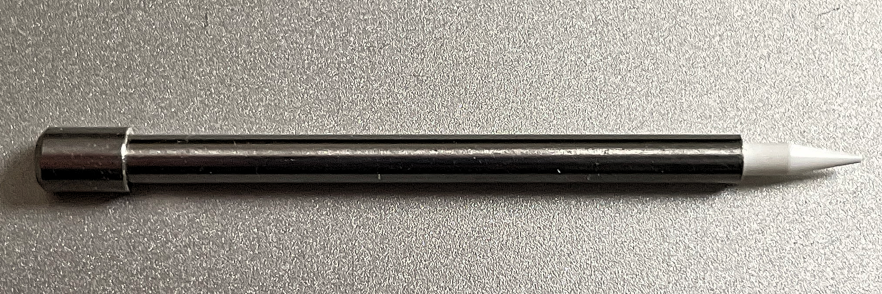

Capillary pin with a ceramic tip

Capillary pin with a ceramic tip The capillary pins produce uniform spots even with printing liquids with high viscosity and are able to repeatedly deposit spots of the same size and equal volume. The capillaries enable depositing of the volume inside the channel, the volume is sufficient for hundreds of spots. Next to the lower risk of cross-contamination, there is the advantage, that samples are not wasted or don’t end up at the washing place before the next pick-up. The capillary pins are made of inert material to avoid contamination. If necessary, the pins can be coated with a coating layer to avoid non-specific binding to the pin.

Split pins

The principle of the split pins is the same as at the capillary pins, the liquid is loaded by capillary forces into a small, closed channel made in the pin. When the pin touches a substrate surface, low volumes of liquid are transferred onto the surface, depending on the materials, shapes, and diameters of the pins. With the split pins it is especially important, the material they are made of, as they are sensitive to deformation due to the tip structure. Next to the deformation, another issue is clogging and contamination, especially when spotting protein solutions. In this case, the solution can be using pins with bigger tips. Unfortunately, then it is necessary to make a compromise between accuracy and clogging because bigger slits can cause lower accuracy of spots.

Silicon pins

Recently, there have been developed silicon pins as an alternative to metal pins. Silicon has many advantages compared to metal, including reproducibility, material properties, and cost-effectiveness. The pins are much lighter and cause less force on the pin tips while printing. The disadvantage is occasionally damaging the substrate coating, producing doughnut-shaped spots. For these reasons, silicon pins are not very often used in microarray spotting.

Spotting with pins

Solid or Capillary Pins | ||

Tip diameter | Capillary diameter | Number of spots for capillary pins* |

| 80 µm | 15 µm | maximum 50 000 |

| 100 µm | 20 µm | 50 000 |

| 140 µm | 30 µm | 35 000 |

| 200 µm | 50 µm | 22 000 |

| 300 µm | 60 µm | 9 000 |

| 350 µm | 100 µm | 7 000 |

| 500 µm | 140 µm | 1 500 |

| 700 µm | 180 µm | 1000 |