CONTACT PRINTING or SPOTTING

The printing, spotting or dispensing methods can be categorised according to the spot formation as contact and non-contact. The contact printing is an older method, where the contact pins are used and is based on a direct contact of the printing needle with the printing surface. Contact printing is a preferred method in case of high amounts of different samples, high amount in this case means thousands of samples.

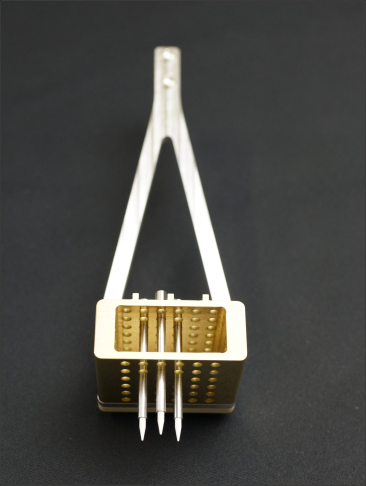

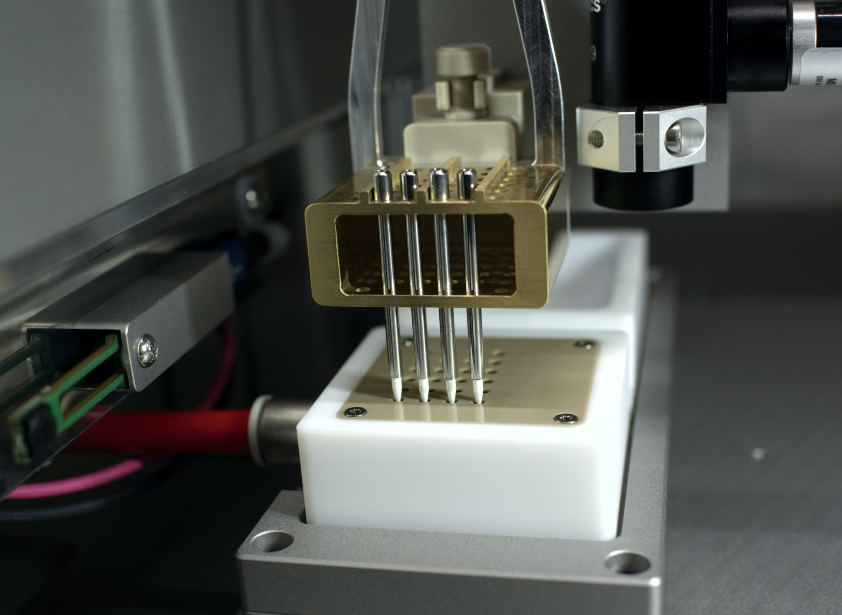

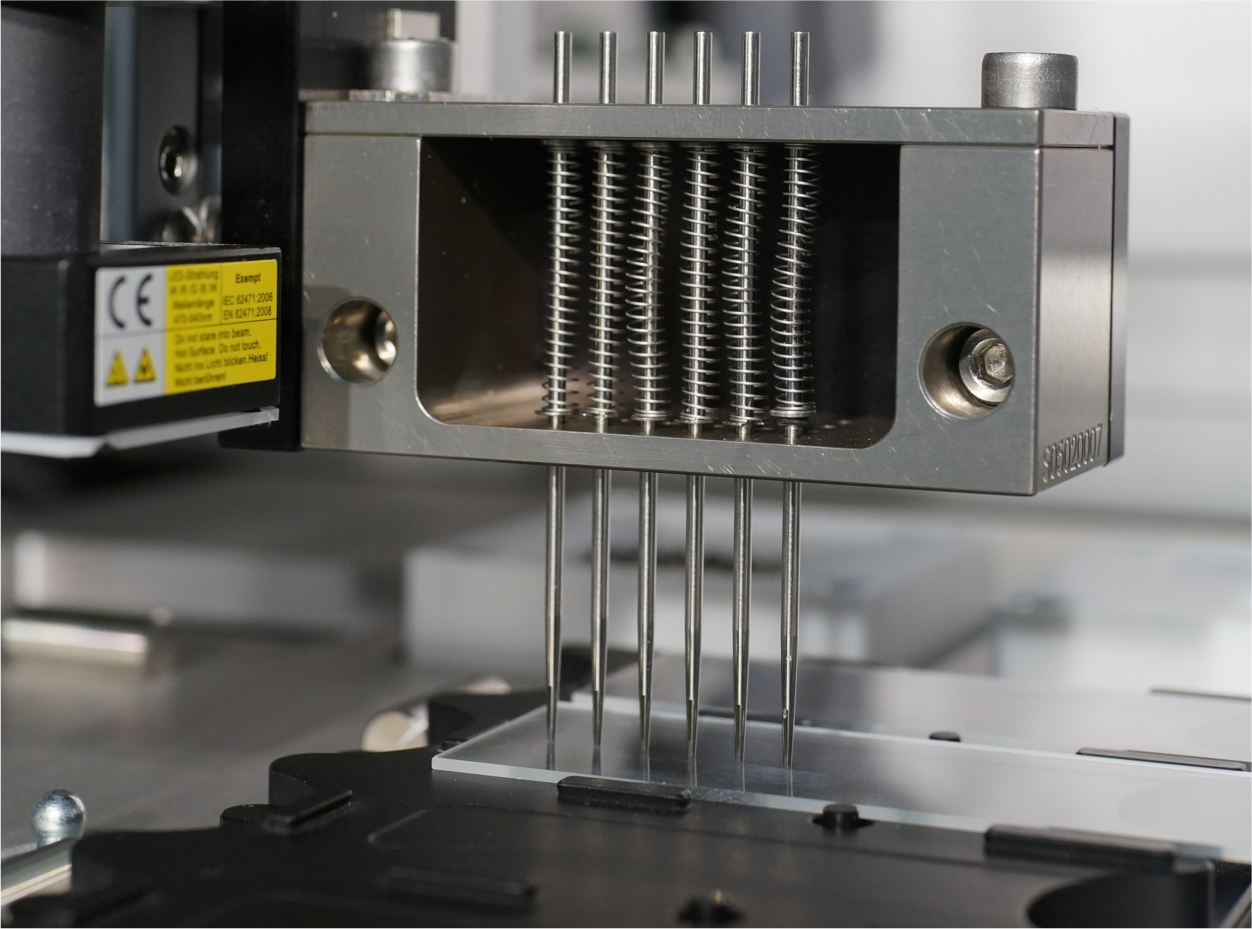

The own process of printing is robotically controlled. Pins are placed in the printing head, which contains from one to dozens of pins, that are repeatedly dipping themselves into wells with fluids. Usually there are 16, 64 or 96 pins mounted in the printing head. The spacing is 4,5 mm or 9 mm, the reason is, that the pins should fit perfectly to the 96 or 394 wells of commercial microtiter plates.

The robotic head and pins must travel back and forth between the substrate deposition site, which unfortunately increases the printing time. It is known that time is money, in this case it is possible to save time by equipping the instrument with fluidic channels. Where money shouldn’t be saved on is the environmental equipment – good control of temperature and humidity, as the samples on pins can very easily dry out. Then there happens unexpected errors in the array, samples on the pin get dried out or clogs.

Large number of pins in the robotic heads are usually accommodated in oversized pin holders, for smooth insertion and comfortable pin removal or exchange. The pins are not rigidly fixed in the head, while depositing the drops, they are naturally wobbling within the holder. It can cause that a few pins will not be aligned to contact the printing surface at the same height or time as all other, and the array will show errors. How to avoid it? The best solution is to think about it already during construction of the head and change holding of the pins, that they wobble as less as possible.

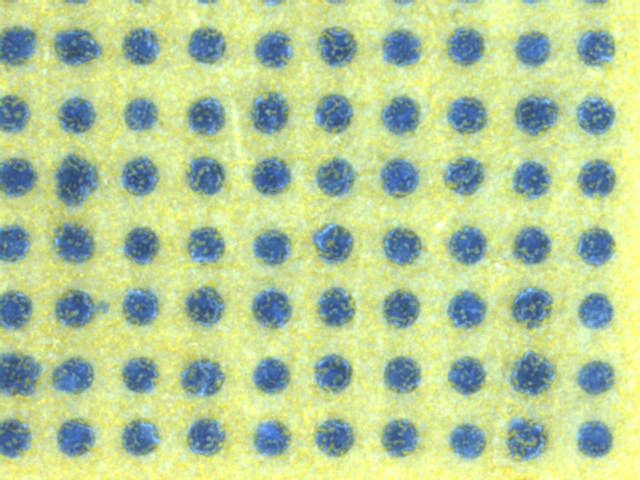

The robot captures a known volume of a solution to each pin and then lightly touches on the substrate. The volume of the picked-up sample depends on the diameter of the pin, solution properties and other chemical reactions. From the very beginning, there were used solid pins; they are suitable for printing just a few same samples, as they don’t have any space where to “store” the liquid. The printing result depends then on a good quality pins with a precise diameter. Solid pins are easily cleanable, easily handle viscous samples, do not clog; but their production is not as simple process. They are made of material resistant to washing, chemical and rinsing process, usually from steel, titanium, or tungsten.

Next to traditional solid pins there are split, capillary, quill, or silicon pins. They differ by their properties. More will be discussed in the next articles.

Real video of a Pin spotter from our customer's labIn general, contact printing has many advantages and for sure is not “overdate” method for producing arrays. As the main advantage can be mentioned easy maintenance, reproducibility, lower initial cost of the equipment. The disadvantage is higher risk of contamination, carry over, possibility of damaging printing surface, high pin velocity can induce drive of large sample volumes out of the pin resulting in making spots very large.