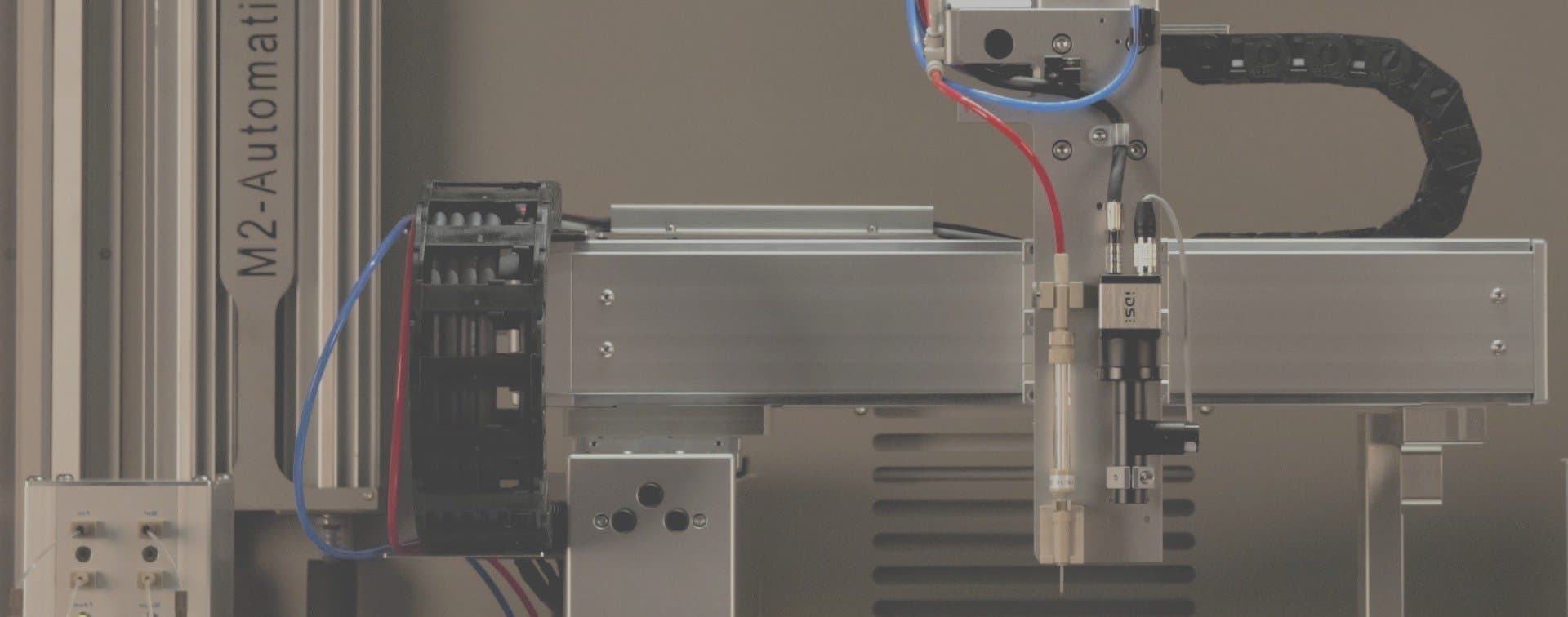

About us

M24You GmbH offers wide range of microdispensing and ultra low volume liquid handling instruments for contact printing and non-contact spotting. Next to the dispensing technology, we provide you with state-of-the-art microarray readers. Beyond selling ultra fast dispensing instruments, we offer you an initial demo spotting and contract manufacturing services. Our scientific background allows us to understand your unique applications and supply you with the best dispensing solution.